5 Powerful Ways Image Annotation Improves Computer Vision

Efficient and effective inventory management is essential for the success of any e-commerce business. Following inventory management best practices and utilizing the right tools and strategies, businesses can look to long-term growth, high revenue, streamlined operations, and enhanced customer experiences.

Negative reviews by customers who want to order products showing in stock in catalog but then show out of stock at checkout.

Large stocks of slow-moving inventory leading to lack of storage, and you pay extra for external storage.

Over purchase of seasonal items leading to stock clearance headaches.

If these sound familiar to you, then it is time you need to invest in ecommerce inventory management. But then manual methods have their limitations and are unable to cope with dynamic data, SKU growth and multiple platforms.

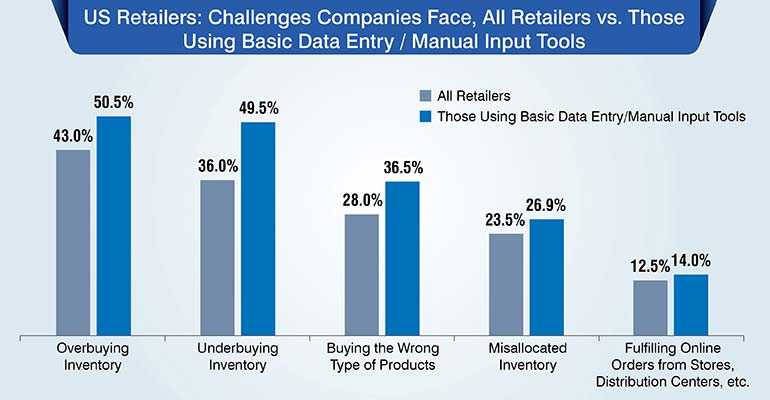

Here are few stats that stands testimony to how traditional inventory management may not be the right approach.

So, inventory optimization, which is the need of the hour, requires advanced technology. Your inventory needs to be always updated and that will result in reduced wastage and storage cost, accurate forecasting, satisfactory order fulfilment, building customer trust and your credibility in the market.

You need to invest in inventory management best practices, and this is what we are going to discuss. Read on to understand the 8 best practices every e-commerce company must follow for optimized inventory management.

Struggling with stockouts, overselling, or messy warehouse data?

Now before we get into the best practices, let us get a little clarity on why we should adopt these best practices. Like what you will achieve by following these practices and how it will affect your ecommerce business.

Let us understand how effective ecommerce inventory management will impact your customers, your operations and ultimately your revenue. Why supply chain optimization, inventory tracking systems and other such tools can help with accurate order fulfilment.

Inventory accuracy helps your ecommerce business stay profitable in multiple ways. Most important your products will never go out of stock, and that will keep your customers always happy. They will start trusting your platform and will always come to it for any requirements. Because they know that your platform will always have accurate inventory information and timely order fulfilment.

Having the right stock, more nor less, will help with cost optimization. Having more stock will require storage cost and the products may also go obsolete. While less stock may often see customers leaving dissatisfied with products not available.

Tracking sales data and inventory levels makes you better equipped to handle demand forecasting, and you know which products to stock and how much to stock. Inventory management software also automates many processes saving both your time and resources.

So, it is not just a stunning catalog that you need; you also need a great inventory management system in place.

And for efficient inventory management you must follow some best practices and here we list 8 most important ones you must follow.

Looking to streamline your inventory with expert support?

It helps your e-commerce business run smoothly, serve customers better, and avoid costly mistakes. Here are the 8 best practices you must follow to keep your inventory accurate and make profits.

Having a centralized inventory tracking system is your first step towards efficient inventory management. This is the most important practice you must follow. Have a centralized tracking system where every inventory related activity can be tracked at a single place.

You know how important real time visibility is especially when you have multiple stores and you operate across multiple channels. Having all your data accessible at one place gives you clarity on your stocks and gets easy to monitor. So, you neither overstock nor understock.

With the use of centralized inventory tracking systems, you get comprehensive reporting capabilities, allowing you to track inventory performance, identify trends, and make informed decisions.

Some common centralized inventory systems include Warehouse Management Systems (WMS), Cloud-based Inventory Management Software and Enterprise Resource Planning (ERP) Systems.

Having a centralized tracking system improves inventory performance, reduces costs, and improves operational efficiency.

A centralized tracking system helps you monitor all your stocks but how do you decide which products you must stock which products are not needed?

And for that you need a well-placed demand forecasting tool.

When you invest in a good demand forecasting tool you predict sales trend and better optimize stocks. For example, a retailer predicted festive surge of printed tops and stocked well in advance to avoid any stock out. You can even plan your product promotions with predicted buying behaviour.

It is a great tool which helps plan your business well using historical data, market trends, algorithms and analytics. These tools collect data from multiple sources. The tools collect data on seasonal demands, economic indicators, weather conditions, market trends etc. that helps them forecast future demands and customer behaviour.

Getting to the pulse of your customers is half the battle won. You get data on what they need, when they need and how much will be needed. It is a win-win situation for all. Customers get what they need, your stocks are never under or over stocked. You customers are happy, and you save on costs associated excess stocks.

Getting these tools integrated into your system is simple; they easily integrate with your ERP or inventory management systems. They work on a auto mode and keep updating stocks needed.

Now that you have your demand forecasting tool in place that will take care of any predictions but how do you handle unexpected demand surges. They can happen any time. And for that reason, you need to optimize safety stock levels.

Safety stock tools account for lead-time variability, which forecasting alone cannot manage. Any sudden unplanned things like logistic breakdown, weather changes etc. can cause revenue loss and this is where safety stock levels come to rescue.

Say for instance, there is a sudden spike in the sale of electronic gadget due to some celebrity endorsing the gadget and you don’t want to get out of stock mid sale as this will lead to cancelled orders and deliveries may also get delayed. Your market credibility may also take a dip.

Having an extra inventory can protect against unexpected fluctuations in demand or supply chain disruptions. You will always have stock as a buffer to tackle any uncertainties.

Implementing inventory management software, safety stock calculation and collaborating with suppliers support inventory optimization.

Your stock calculation plays an important role in keeping the stock optimized. But often certain stocks go redundant, and you must remove them to save space and optimize your stocks. How do you do that. Manually doing this is next to impossible.

This is where SKU optimization comes in. This will help you find out stocks that are not performing. You can either remove them or optimise the performance.

To explain better, suppose a retailer is selling t-shirts of 10 colours and out of that, only 6 colours sell the maximum. The retailer can discontinue the other 4 slow-moving and unprofitable colours, which will reduce storage space and costs too.

The benefits of a well-optimized inventory are multiple, which ultimately help with your revenue and overall business operations.

SKU rationalization is a great way to remove or optimize underperforming stocks. The other way to save on storage cost is to buy products as and when it is needed.

This is done through Just-in-time (JIT) inventory management. It is a strategy where materials are purchased and produced only as needed, minimizing waste and storage costs.

But then for this your forecasting must be accurate and you also need to have good connection with your suppliers. The arrangement should be such that the product is made available to you whenever you require.

This approach works best when production processes are synchronized with material deliveries. Say, for example, you own a furniture store. Now you would need materials like fabric, wood, etc only you receive an order. Storing such materials without an order will unnecessarily increase your storage cost. So, you get just before you start production.

After managing your stocks, you also need to have a control on all your warehouse operations such as receiving goods, storage, packing and shipping. The real time visibility check ensures less errors, storage optimization and accurate order fulfilment.

So, how do you do that?

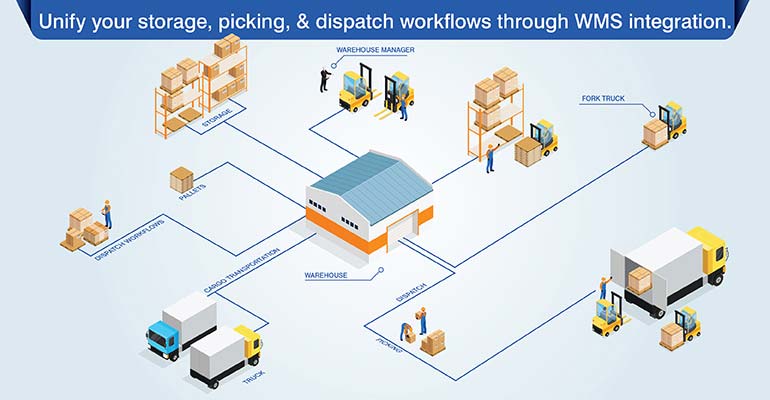

You integrate a Warehouse Management System (WMS) that helps you connect with other business software systems to streamline operations and improve data flow.

You can link WMS with systems like ERP, CRM, and accounting software. There is inventory synchronization across all channels. This improves the overall efficiency of the system benefiting organization.

Some examples of WMS Integration include ERP Integration, CRM Integration, E-commerce Integration and Accounting Software Integration.

Real-time data analytics empowers businesses with up-to-the-minute insights into inventory levels, enabling faster and more informed decisions for optimized inventory management. To implement this, you need to have systems in place that track inventory levels, sales data, and other information, all in real time. And then comes the next step, where you analyze the data to identify trends, predict demand, and optimize stock levels.

The benefits of this can help your business perform at an optimal level, and your systems become more streamlined, leading to higher revenue.

Technologies that can be used for real-time tracking include RFID (Radio Frequency Identification), IoT (Internet of Things), and Cloud Computing.

We all know that faster refunds and hassle-free returns make a customer happy and start trusting the brand. That is why it is important to establish strong returns and reverse logistics workflows. This ultimately benefits a business by improving customer satisfaction, reducing costs, and enhancing sustainability.

You need to manage the process of receiving, inspecting, repairing, reselling, or recycling returned products, ultimately turning a liability into an asset. Of course, this has its challenges, like logistics costs, inventory management, and meeting customer expectations. But on the other hand, it offers long-term benefits in terms of building your brand image.

Managing e-commerce inventory isn’t as simple as it looks. Every time a product is delivered on time, it goes through a long complex process. There are multiple hurdles and challenges that needs tackling to make the process smooth and quick. Here are some of the key challenges.

It is extremely important for you to choose the perfect inventory management software suitable for your project needs. Because if you choose a wrong one you may land in trouble. It can lead to data silos, inaccurate stock counts, workflow disruptions and integration issues. Look for systems that can be customized because if they lack customization you may have to invest in training. All these can increase cost and impact your business.

Outsourcing inventory management is a great way to address all these challenges. Inventory management domain experts with years of hands-on experience assure you of data accuracy, business continuity and constant monitoring all the time.

The success of any e-commerce platform depends on effective inventory management. This is not just about tracking your stocks; it is about a comprehensive system that supports your growth and keeps customers happy. Best practices that we discussed in the blog, such as keeping a centralized system, establishing strong return policies, real-time analytics, and integrating warehouse management, are some of the best practices one needs to apply.

Every single step is important, and every strategy you use will take you closer towards improving order accuracy, speeding up fulfilment, and enhancing customer experience. So, you must start if you have not, and if you already have, build on it so that it streamlines your business. The bottom line is that there is no option. Inventory management is a necessity.

What’s next? Message us a brief description of your project.

Our experts will review and get back to you within one business day with free consultation for successful implementation.

Disclaimer:

HitechDigital Solutions LLP and Hitech BPO will never ask for money or commission to offer jobs or projects. In the event you are contacted by any person with job offer in our companies, please reach out to us at info@hitechbpo.com

Leave a Reply